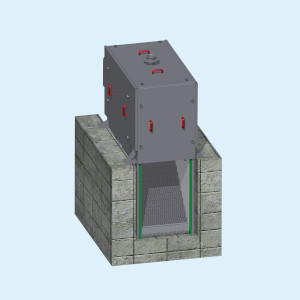

Step Screen,

is equipment used for the solid-liquid separation operations, as a system for the mechanical separation of grits, detritus and floating solids. Its typical field of usage is in the wastewater treatment plants, where an effective primary screening is the best way to achieve efficiency in the following processes

Main features of Step Screen:

- Customized equipment

- Series of laminas with a step design

- Available in stainless steel AISI 304L or 316L

- Simple and robust construction

- Absence of overly complicated referral

- No chains or deformable quadrilaterals

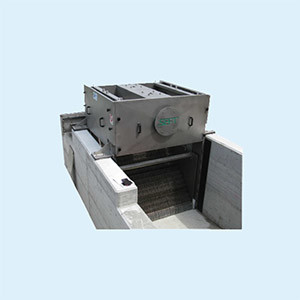

All transmission systems, bearings, shafts and couplings are out of the channel (no contact with the treated fluid and easy maintenance)

The cover is designed to protect the step screen till the channel border, protecting also the moving parts from the weather (allowing open air installations and acting as a CE-norm protection system for the safety of plant personnel)

The filtering unitis divided in two interpenetrating blocks, one mobile and one steady, whose relative movement produces a steady going of the filtered solids towards the discharge, leaving the filtering spaces always free and clean. Furthermore, the deposit of the solid particles on the screening bed can be used to improve the percentage of removed floating debris.

When choosing the filtration spacing, must be took into account the wide filtering surface that allows to work with low fluid speed through the grid, reducing the resulting headloss.

send your request: