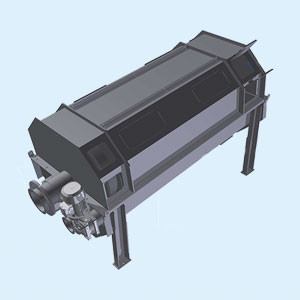

The internally fed rotary drum screen IFS is composed of a tank and a spiral connected to a drum for the screening transportation.

The drum screen is made of a perforated plate and the perforated holes profile diameter can be selected on the customer's needs.

The drum screen is supported by nylon wheels, and it is operated by a gearbox. The filter is fed through a nozzle placed in the front of the machine.

A diffuser spreads the water on a large area of the screen which, rotating, separates water from the organic particles contained.

The filter is cleaned through a washing system consisting in a tube with spray nozzles for pressurized water.

During equipment operation, the water is conveyed at the outlet placed in the front of the machine, while the screenings are transported by the spiral towards the screening outlet in the back of the machine.

The screen inclination contributes to the dewatering of screenings, the screen is also equipped with a by pass pipe to avoid overflows with a predisposition for a overflow sensor.

Advantages of Internally fed rotari drum screen:

- Customized equipment

- Improved double washing system equipped with high performance nozzles.

- Easy maintenance support wheels, replaceable without having to remove the filtration cylinder.

- Special chain drive system that does not require tensioning adjustment, for a higher durability over time and stability of performance.

send your request: