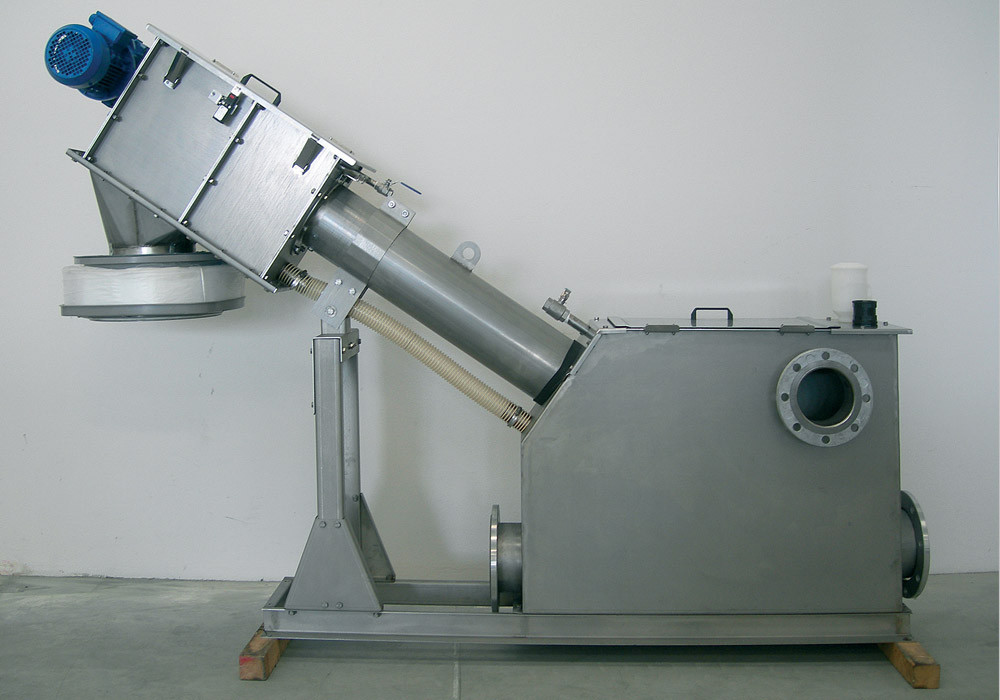

The Screw screen in tank is equipped with fully sealed stainless steel container or tank to allow installation where there is not provided a concrete channel.

The container / tank is complete with flanged stub pipe of input and output, the container / tank can have a cassette side bypass rake screen (optional).

At the end of conveying section is assembled the compactor with the related discharge mouth.

Same principle of operation of the series FC, with the simple addition of the container.

Advantage of Screw screen in tank:

- Custom project

- High percentage of solid removed

- Low speed of rotation and no intermediate supports

- Self-cleaning with brushes fit on the screw

- Low maintenance and low initial investment

When required, the compactor is installed in the upper part of the screw conveyor at the end of the grating transport area and performs the compaction and dehydration of the solid to reduce its weight and volume up to 50%

send your request: